Cellular Polycarbonate Panels

Ideal for applications requiring high light transmission, impact resistance, and the ability to bend in cold conditions, from commercial uses to architectural applications.

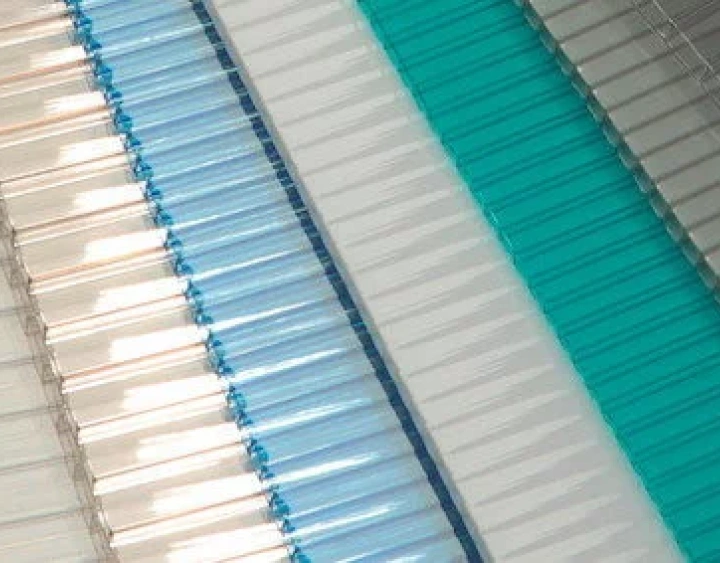

Macrolux Multiwall polycarbonate sheets offer unparalleled quality. They are available in a wide variety of thicknesses, colors, and specialties to meet the demands of the national and international markets.

Features and Advantages

Translucent cellular polycarbonate sheets contribute to energy savings. Learn about the various benefits and advantages you can have in your buildings with Macrolux Multiwall.

Impact resistance

Energy saving

Self-extinguishing

50% lighter than glass

UV protection

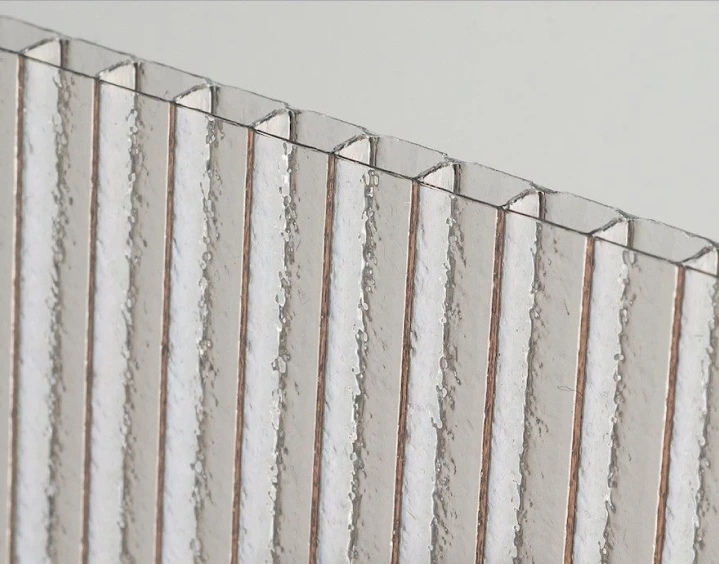

Macrolux Multiwall polycarbonate sheets are an extruded plastic laminate based on high-tech polycarbonate resin. They come with a protective layer to counteract the weathering effects caused by UV rays. Macrolux Multiwall polycarbonate sheets have been designed for industrial, commercial, architectural, and residential applications, meeting the needs for natural lighting and thermal insulation.

Our polycarbonate sheets offer a 15-year warranty against yellowing and loss of natural light, in addition to various benefits such as excellent natural light transmission, protection against UV rays, impact resistance, thermal and acoustic insulation, self-extinguishing properties, and resistance to extreme temperatures ranging from -40°C to 120°C. Thanks to its unparalleled flexibility, they allow more freedom for design, facilitating cold bending for a modern and elegant appearance.

Applications

Cellular polycarbonate sheet Macrolux Multiwall for greater variety, our polycarbonate sheet can be used in different applications thanks to its strength and durability.

Industrial Multiwall

Macrolux Multiwall provides thermal insulation in industrial constructions. Being a polycarbonate sheet, it will provide natural lighting. It can be used for roofs and walls of warehouses, storage buildings, and industrial parks, flat light strips, barrel vaults, sawtooth structures, windows, corridors, etc. The sheet is self-extinguishing, so it does not spread fire, increasing safety in your industrial spaces.

Commercial

Translucent polycarbonate sheet for domes, roofs, and walls for commercial plazas, warehouses, self-service stores, restaurants, and any type of business that requires coverage with aesthetics and resistance. Macrolux Multiwall provides cost savings in support structures due to its lightweight nature, contributing to the lighting, safety, and aesthetics of all your projects.

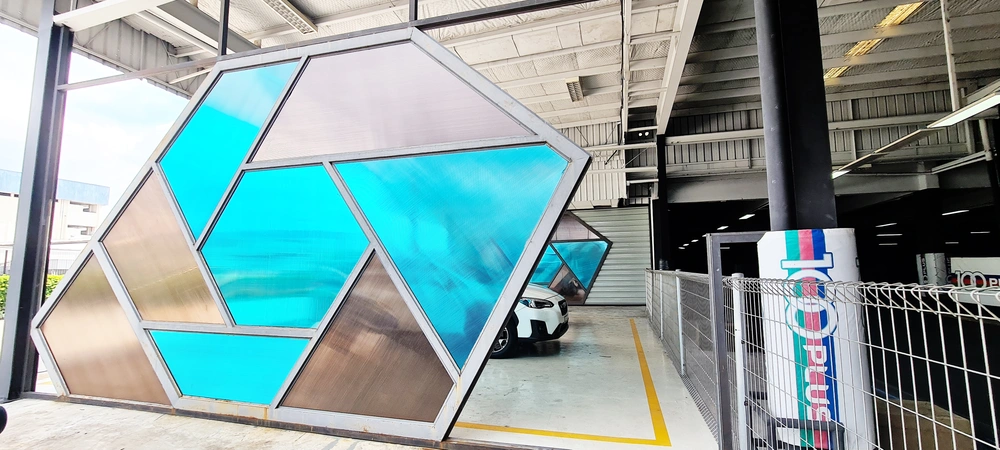

Architectural

Glazing (glass replacement) in architectural constructions: sports pavilions, stadiums, easy to install and low maintenance, for greater aesthetics in your spaces. Do you have a project in mind? Request more information about our polycarbonate sheets.

Greenhouses

We have different types of cellular polycarbonate sheets with various specifications, IQ-Relax for additional heat reduction and No-Drop for humid conditions, for greater protection in your greenhouse. Our cellular polycarbonate sheet can be used in roofs, walls, and airlocks of any type of greenhouse that requires up to 80% natural light transmission and heat retention inside.

Residential

Macrolux Multiwall polycarbonate sheets can be applied in corridors, carports, terraces, patios, and more. Thanks to their lightweight nature, they allow for easy and quick installation, creating bright spaces with high UV protection and aesthetics.

Industrial Multiwall

Macrolux Multiwall provides thermal insulation in industrial constructions. Being a polycarbonate sheet, it will provide natural lighting. It can be used for roofs and walls of warehouses, storage buildings, and industrial parks, flat light strips, barrel vaults, sawtooth structures, windows, corridors, etc. The sheet is self-extinguishing, so it does not spread fire, increasing safety in your industrial spaces.

Commercial Multiwall

Translucent polycarbonate sheet for domes, roofs, and walls for commercial plazas, warehouses, self-service stores, restaurants, and any type of business that requires coverage with aesthetics and resistance. Macrolux Multiwall provides cost savings in support structures due to its lightweight nature, contributing to the lighting, safety, and aesthetics of all your projects.

Architectural Multiwall

Glazing (glass replacement) in architectural constructions: sports pavilions, stadiums, easy to install and low maintenance, for greater aesthetics in your spaces. Do you have a project in mind? Request more information about our polycarbonate sheets.

Greenhouse Multiwall

We have different types of cellular polycarbonate sheets with various specifications, IQ-Relax for additional heat reduction and No-Drop for humid conditions, for greater protection in your greenhouse. Our cellular polycarbonate sheet can be used in roofs, walls, and airlocks of any type of greenhouse that requires up to 80% natural light transmission and heat retention inside.

Residential Multiwall

Macrolux Multiwall polycarbonate sheets can be applied in corridors, carports, terraces, patios, and more. Thanks to their lightweight nature, they allow for easy and quick installation, creating bright spaces with high UV protection and aesthetics.

Cellular Polycarbonate Panels

Our cellular polycarbonate sheets are easy to install. In this video, we show you a glimpse of the process and some tools and accessories you need for proper assembly. We also provide instructions, and you can read our blog for TIPS ON A PROPER INSTALLATION OF POLYCARBONATE PANELS.

Image gallery

Installation of cellular polycarbonate sheets for various applications.

Product Range

Double UV Protection Polycarbonate Sheets

These polycarbonate sheets have UV protection on both sides for superior weather resistance, helping maintain high light transmission for an extended period and providing advantages in cutting and installation.

Frostyglass Polycarbonate Sheets for Increased Natural Light Diffusion

These polycarbonate sheets have a frosted glass appearance, providing increased light diffusion and a distinctive aesthetic finish.

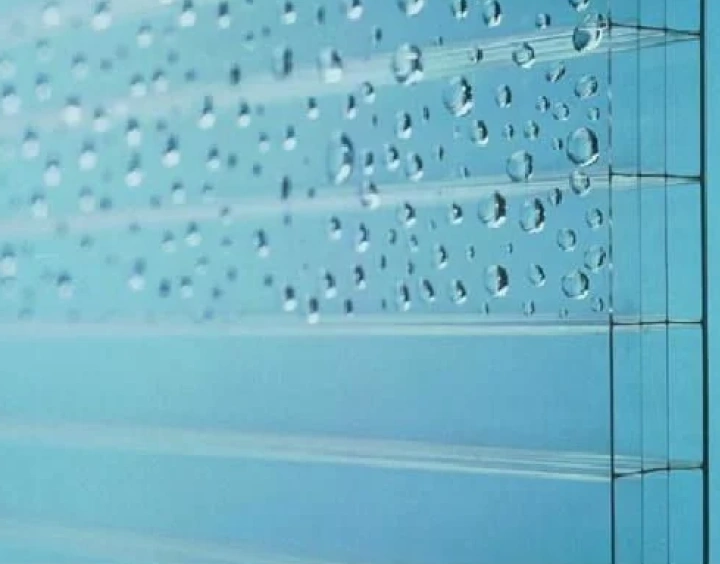

No-Drop Polycarbonate Sheets for Humid Conditions

These polycarbonate sheets feature a special water dissipation layer that prevents the formation of droplets in humid conditions commonly found in greenhouses.

IQ-Relax Polycarbonate Sheets for Additional Heat Reduction

These polycarbonate sheets are specially developed to reduce interior heat. They have advanced solar control properties that automatically adapt to environmental conditions: allowing natural light to pass through while preventing the entry and exit of most heat and cold. A thermal reduction of 13°C has been proven compared to standard polycarbonate laminates of the same thickness. Macrolux IQ-Relax contributes to environmental sustainability and the attainment of LEED credits